Getting started

When hanging an interior door, the first thing to do is check for proper sizing of the rough opening. The opening should be two inches wider and one inch taller than the nominal size of the door. The second thing to check is the proper handling of the door.

When checking for proper handling, it is crucial to be precise. Stand with your back against the door frame on the side where the hinges will be. If the door opens to your right, it is a right-hand door; if it begins to the left, it is a left-hand door. Next, meticulously inspect the inside of your opening, the finished walls for plumbing, and the floor for leveling between the hinge and the latch side. Usually, things will be slightly off, so note how far from plumb things are. This diligence will ensure a successful door installation.

Remember, the key to success in this door-hanging method is to take it step by step. Leave the door alone, except for measuring and removing the shipping fasteners, until your shims are installed on the hinge side of the rough opening. Keep the door centered in the rough opening when figuring out your shims’ layout. One exception to this is if one side of your rough opening is remarkably close to an adjacent wall. In this case, you have the reassurance of adaptability, allowing you to add thicker shims on the side of the rough opening closest to the wall. This adaptability empowers you to install casing without ripping it to a smaller dimension than stock. Each situation is unique, and you can adapt the process to your specific needs, making it a versatile solution for any interior door installation.

What tools do you need?

To hang a pre-hung interior door, you will need essential hand tools like a utility knife, hammer, tape measure, screwdriver, and 48″ or more extended level. These tools are the backbone of any DIY project. However, a few power tools can significantly speed up the process. A cordless drill or impact driver, circular saw, planer, oscillating multi-tool, finishing nailer, and compressor are not just luxuries but time-savers. They will make your work more efficient and less time-consuming, sparking excitement and motivation as you see your project come together in a shorter time.

Checking for plumbing and installing shims

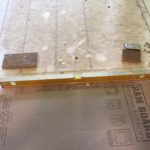

When you are ready to install the hinge side shims, try to locate them behind the hinges. I mark the hinge height on my 78″ Stabila level with a marker or painter’s tape. This way, you must place a pair of shims behind the level from opposing sides and slide them in and out to create the desired depth. Then, nail them to the studs using a hammer or finishing nailer. After the first shims are secure, move on to the following sets. Take your time, use your level, and nail them off.

If you are sure your shims are plumb, now would be an enjoyable time to cut the extra length off. A good sharp utility knife works well. Score the shim several times to be set back from the drywall edge. After scoring, they usually snap easily. Don’t pull the shim loose from the nails. I prefer an oscillating multi-tool. It zips right through the shims like butter. You can wait until the jam is installed too.

Guide to setting the jamb

Before setting the jamb, consider the installation height and whether to trim one or both legs. If the floor is uneven between the hinge and latch sides, trimming might be necessary. If one side is at least one-eighth of an inch higher and the finished flooring is a solid surface, trim the jamb by the difference. For carpeted floors, do not trim unless the difference is more than three-eighths of an inch. The flooring will determine the height. If the flooring isn’t installed yet, use scrap material and underlayment as spacers on the hinge side. Place the thin end of a shim on the spacer or finished floor. For carpeted floors, position the thick end of a shim under the hinge side jamb, approximately 5/16″ to 3/8″.

If the jamb is around 1/16″ broader or narrower than the finished wall, you can divide the difference between the two sides rather than set it flush on one side with a gap on the other. Additionally, if the difference in width is one-eighth” or larger, you will need to plane the jam or add jamb extensions. Up to this point, everything has been prepping work. Now, the fun part begins.

Installing your new door in the rough opening

The next step in the interior door installation process involves setting the door assembly in the rough opening, ensuring the hinge side touches all the shims. Check the head jamb reveal before nailing; the gap on the latch side should be even or smaller. Use a speed square or a straight edge to align the most visible side of the door with the finished wall at the top, then nail through the top shim with 2-1/2″ 15ga finish nails. Continue working down to the next shim and then to the bottom, keeping the jamb edge flush with the finished wall. To secure the door, remove a screw from each hinge with a screwdriver or cordless drill, and replace it with a 2-1/2″ or 3″ screw that reaches the framing. Ensure the screws are snug but not overtightened to avoid distorting the jamb, which could make hanging the door more difficult.

Finishing touches and last thoughts

Once the hinge jamb is secure, you can work around the head and strike the jamb. Nail in extra shims to keep an even reveal or gap around the door. You will find that each leg jamb will need 5 or 6 shims to keep them straight. The strike plate is always one place to install shims. The top may need just one in the center or 2 or 3 pairs. Now, the door assembly will be installed appropriately and with all the required backing to keep it operating for years.

One Comment

James Mason

August 18, 2016 at 9:19 pmGreat write up Paul, well laid out!