Metabo HPT has released a new 36V MultiVolt Cordless Triple Hammer Bolt Impact Driver (WH36DCM) as the next generation, replacing the MultiVolt 36V Brushless Triple Hammer Impact Driver (WH36DB). This kit will include two 2.5Ah MV batteries, a rapid charger, and a hard case. The new impact driver adds a new innovative solution, making any job site even more productive. It offers better power, compact size and weight, faster speed and modes, visibility, and resistance. It accepts any Multivolt battery or AC Adaptor. A lifetime lithium-ion tool body warranty, a 2-year lithium-ion battery warranty, and a 1-year charger warranty also cover the new impact driver.

Tool Features

This new impact driver offers many new innovative attributes compared to previous versions. First, it has a faster driving speed, more torque, and decreased vibration. It has a power of up to 1,903 in-lbs of torque, 0-3,400 RPM, and 0-4 100 BPM. It is very compact, at only 4-½-inches long, and lightweight at only two pounds. There are 5-speed modes to control fastening screws and bolts. A responsive variable speed trigger provides you with complete control. 3-LED lights give you better visibility in dark areas and minimize shadows. The driver is water and dust-resistant with an IP56 rating. And lastly, a brushless motor offers longer run-time, power, and extended durability.

36V MultiVolt Cordless Triple Hammer Bolt Impact Driver

Below, check out our Tool Torture evaluations on the older generation, the 18-volt lithium-ion brushless triple hammer impact driver by Metabo HPT.

The Hitachi Triple Hammer Impact Driver is the first of its kind; by using three internal anvils to power this 18-volt cordless tool instead of the industry standard 2, Hitachi has increased impacts per minute and torque. Is this increase a gimmick, or does Hitachi know what they are doing?

Stress Testing

Imagine trying to perform a task that could not be completed. To simulate this, we used a three-eighths-inch threaded rod, added a double nut set up to one end, and clamped the other into a vise. We then started the Hitachi Triple Hammer on the double nut to see how long it could hold up.

The impact driver continuously hammered away for 45 seconds and then stopped. After looking briefly shocked, we remembered that a thermal overload had been built into the motor to prevent damage. At least it worked as designed. We removed the battery, reinstalled it to bypass the thermal overload, and started the test. We used the impact driver for another 5 minutes before stopping the test. The only issues we noted were that the handle was getting hot, and the battery started to wear down slightly.

How does the IP56 rating hold up?

In a previous Acme Tools video, we saw the Hitachi Triple Hammer get dunked underwater, and it still performed everything asked of it. How well will it do if we pack it with sawdust?

The sawdust was no match for this Hitachi impact driver. We started with a couple of handfuls right at the intake cooling fins, and when it continued, we decided to pour the rest into the unit as it was running. Overall, the Hitachi Triple Hammer Impact Driver ate a quart of sawdust and continued.

Accident Proof

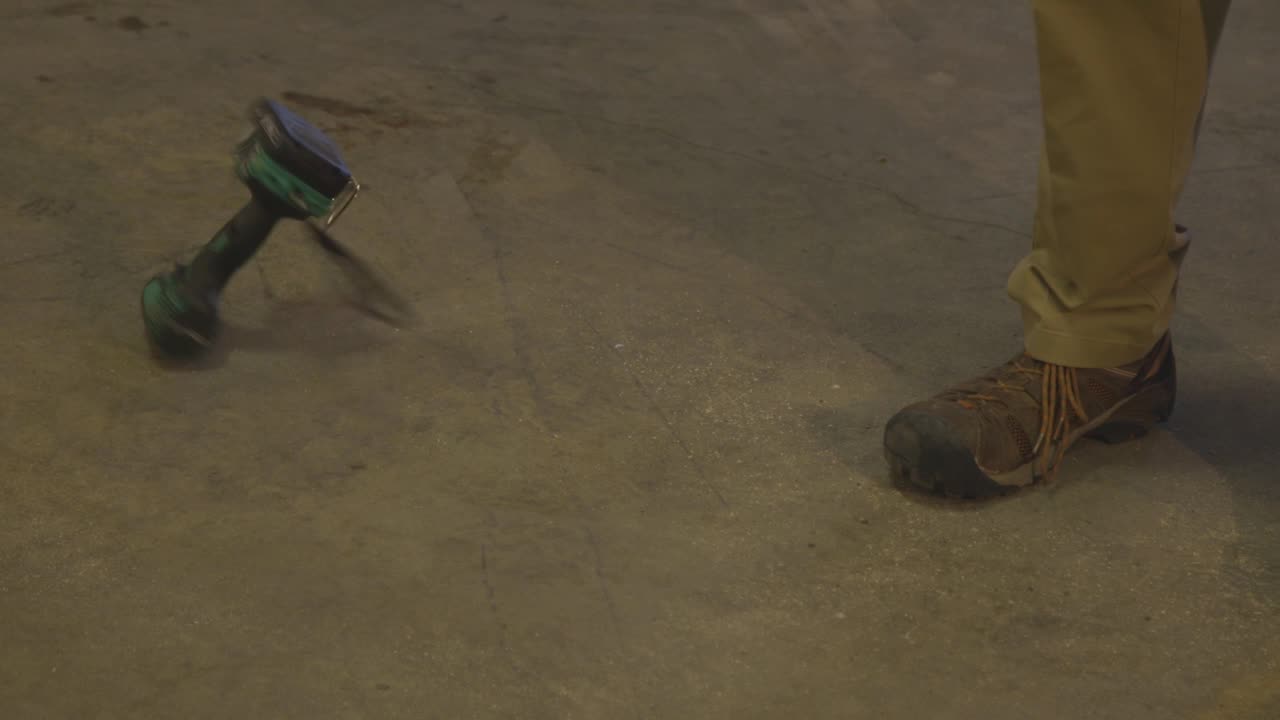

Accidents happen, and tools are dropped. A more critical question is how your tools will manage the drop. We evaluated the Hitachi Triple Hammer Impact Driver with real-world heights, and here is what we found. Typically, the impact driver is in or clipped to your tool belt while you work, so let’s start there.

No problem with that height. Working on a ladder is also a standard workplace height, so let us see how it works from a little higher up, like 6 feet up from the ground.

There is no problem with that height, either. Instead of simulating a taller ladder, we decided to step it up a couple of notches. Many HVAC Technicians, Electricians, and plumbers work on scissor lifts all day. Eventually, your tool will take a fall, so let us see how this Hitachi impact driver manages a 15′ fall.

There were no critical issues with the fall from the scissor lift. There was some cosmetic damage, but the nose pieces were designed to keep debris from entering the front of the tool, snap right back into position, and run fine.

Test Conclusion & Final Thoughts

When we started the tool torture on the Hitachi Triple Hammer, we were all a little hesitant about how it would perform, but after putting it through the paces, it is easy to say that we are overly impressed with the quality of this tool. Not only did Hitachi develop a tool that can impact more often and harder, but they also included technology to prevent overheating if overworked, making it durable enough to withstand water, dust, and drops. The Hitachi Triple Hammer Impact Driver is one tool that can be relied on daily.

2 Comments

Pottski

May 27, 2017 at 9:07 pmThat last drop test sounded like something wasn’t right…. you can hear it when he pulls the trigger and I think he knew it too because he didn’t hold the trigger very long. I had my dewalt dcf886 kicked off a second floor balcony on to a concrete slab and all it did was bend the bit, no damage to the inside or outside and the battery didn’t slip. That was a year ago and the tool still runs just as strong as it did when I bought it 3 years ago.

Dave

July 7, 2022 at 1:51 pmThey are tough in most respects, but the direction switch is FRAGILE, and replacements are NLA.

The ‘wings’ that actuate the direction pin atop the switch are tiny plastic. After just a dozen hours of field use, the wings break off, leaving the tool stuck in one direction. You can dissassemble and glue the wings back on, they’ll break off after a few hours, leaving you in the same situation.

Aside from this fault, they seem pretty tough, but because of this critical flaw, they’re useless.