Sure, a hand-operated drill is very efficient at making holes. But now, with your new drill press, you have really stepped up your game! Your drilling will be more precise, and due to the drill presses larger motor, you can use more significant bits to make bigger holes. The following tips will help you get the most from your new tool and turn you into a true drill master!

The Need for Speed

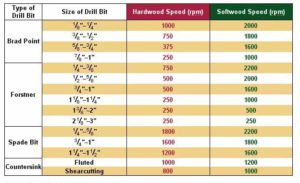

Always be aware of the speed needed for each operation. For safety and to produce a clean hole, running the tool at the correct speed is essential. The drill press’s manual will provide speed guidelines based on bit size and the material you’re drilling into. Router bits often come with these guidelines as well.

Generally, slower speeds are used for more significant bits and drilling into metal. Faster speeds are used for smaller bits and when working with wood. Usually, the speed is adjusted by moving the drive belt from one pulley to another. The smaller the pulley being used, the faster the speed.

Install the Right Bit

Choose the right drill bit for the task at hand. You’ll want the bit’s diameter to correspond to the hole size needed. Ensure that the bit is appropriate for the material you are drilling into, e.g., wood or metal.

When installing the bit, it’s an excellent habit to unplug the tool to avoid an accidental turn-on. Use the key to open the chuck, slip in the bit, and then tighten the chuck.

Set the Table Height

Adjust the table to the height that’s best for the task. This depends on the size of the item being drilled into and the length of the bit. Most drill presses have a crank that moves the table up and down.

Use A Depth-Stop

A depth-stop will come in handy if you need to drill a hole at a fixed depth (versus drilling all the way through). The drill press has a gauge controlling the distance the spindle travels downward, so you can set how deep the hole is drilled. Read and follow the instruction manual to put your tool’s gauge.

Secure the Material

The torque of the spinning drill bit can violently rip an unsecured workpiece from your hands and even turn it into a dangerous projectile. Use a clamp, vise, fence, or one of the many jigs on the market to secure and align the workpiece to the drill press table.

Get Ready…Get Set…Drill…

Following the above tips, you should be ready to drill your first hole with your new machine. Turn on the power and make sure it’s up to speed before you begin drilling. Using the rotating arms, lower the drill bit into the material at a slow, consistent speed. If drilling to a thick piece of wood, occasionally back the bit out of the hole to remove debris before continuing to drill.

Helpful Accessories

Earlier, vices, fences, and jigs were mentioned to secure the workpiece to the drill press table. But many other accessories can enhance your tool’s productivity. These include a mobile base, a keyless chuck for quick bit installation, a mortising attachment to speed mortise production, and a sanding drum for smoothing curved stock.

You’ve Earned Your Stripes!

You’ve just completed the basic training. Practice with your new machine and complete a few projects, and you’ll be a confident “Drill Sergeant” in no time!

Did you find this article helpful?

Let us know in the comment section below. Do you or someone you know have new tools and don’t know what to do with them yet? We have a “Your First” tool series about new tools in your shop that you should check out. This series will only grow from table saws, cordless drills, routers, and miter saws.

Looking for more tools to expand your shop or a gift for the tool nut in your life? Helping to Always Do Your Best Work, Acme Tools has deals online daily that you can take advantage of without ever leaving the comfort of your home.