Angle grinders can be a very dangerous power tool. You have a blade spinning up to 11,000 RPM that may seem relatively harmless but could lead to serious injury. There are several safety technologies that have been introduced over the years that have made angle grinders safer, but if not used correctly, they aren’t helpful. Whether you’re new to the tool or have been using it for years, it’s always a good idea to read up on proper safety while using your angle grinder.

Our helpful guide will give you a better understanding of how the tool works and how to handle an angle grinder properly. We’ll cover how to ensure your work environment is safe, how to properly choose your angle grinder discs, the best personal protective equipment, and some general safety tips while using the grinder.

Proper Personal Protective Equipment

The first part of angle grinder safety is using the proper personal protective equipment. Your gear could be what stands between you and serious personal injury.

Using an angle grinder can get particularly loud, so hearing protection is always a good idea. Depending on the noise level, it may be an OSHA requirement in the workplace. Anything over 85 decibels mandates some kind of hearing protection, whether it’s earplugs or earmuffs. Depending on the type of grinding disc being used and the material being worked on can alter the noise level.

Face and Eye Protection

Using an angle grinder can get particularly loud, reak items down, dust and materials can get thrown about at very high speeds. If grinding metal, it’s a good idea to wear a face shield as well to prevent hot sparks from coming in contact with your skin. A dust mask or respirator is recommended if working with masonry materials as the dust can be inhaled.

As you grind and cut materials down, they can be sharp, so wear a pair of gloves. They’ll protect against sharp or hot particles and materials. Choose a pair of gloves that fit well but still provide plenty of dexterity while working. A good pair can protect against cuts, abrasions, and heat. Vibration-resistant features are also a good idea to prevent hand fatigue.

Body Protection

A good rule of thumb is to prevent as much skin exposure as possible. Most grinding involves sparks, and getting them on your skin is a good way to ruin your day or even lead to a hospital visit, depending on the severity. Wear flame-retardant or resistant clothing to protect against burns. Don’t wear loose-fitting clothing as it could become tangled in the grinding disk.

Check Your Work Environment

Before you even think about firing up your grinder, there are a handful of items to check about your surroundings.

- Remove any slip or trip hazards. The last thing you want to happen is to fall while a grinding disc is in operation.

- Remove any flammable substances from the area, such as oily rags. Sparks will be flying around, and you don’t want to start the whole workshop on fire.

- Check the ventilation of your workspace to prevent dust and vapor from drifting around the room and breathing them in.

- Ensure your project is secure and supported at a comfortable height where you aren’t bending over too much or lifting the grinder above your head.

Choosing the Proper Disc Size and RPM

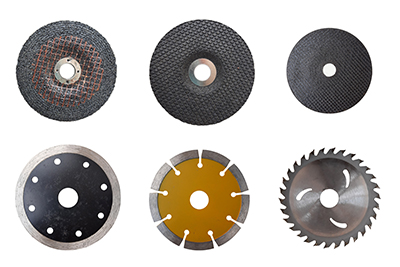

Choosing the wrong angle grinder disc size or not-matching the disc RPM to the angle grinder are some of the leading causes of injury while working with this power tool.

Every angle grinder has a recommended disc size and is there for the safety of the tool and the safety of the user. A larger disc may fit on the grinder, but it doesn’t mean it should be done. The central disc hole will likely be larger than the spindle flange of the grinder, which can cause the disc to wobble. A wobbly disc increases the likelihood of the disc shattering during operation.

After finding the properly sized disc, you’ll want to ensure the maximum recommended RPM is equal to or greater than the capability of the angle grinder. The RPM can be found on the disc itself or the package it came in. Not matching the speed of the disc and grinder can lead to the disc cracking and serious injury.

Another item to check when choosing a disc is pairing the proper disc with the material being worked on, such as a diamond cutting disc for harder stone, and for a specific task, such as a grinding wheel for grinding.

Inspect the Angle Grinder and Disc

Whether you’re working with a brand new disc or a used one, you should always inspect it before use. Look for any cracks, chips, or any other damage that could lead to unsafe operation. Also, check the disc is properly tightened. Use a pin wrench to tighten it if the disc feels loose. Keep in mind some manufacturers produce grinders with locking mechanisms that don’t require a wrench.

Give the actual angle grinder a once-over if you haven’t used it before or come back to it after taking a break. Check that the handle and guard are secured firmly in the correct position. Run the angle grinder at full speed for about a minute and check if you can feel, hear, or see anything wrong with its operation. Ensure there is a guard properly secured to the angle grinder, and it can be maneuvered if it has that option.

Inspection should especially be done if you weren’t the last one to handle the disc or grinder. Someone could have forgotten to remove a damaged disc or possibly dropped the grinder and not noticed it was damaged.

Operating the Angle Grinder

While operating an angle grinder, there are various things to consider that will ensure your safety and the safety of those around you.

- Maintain control of the angle grinder with one hand on the side handle and the other on the back of the grinder. This gives you maximum control and leverage over the tool.

- Grinding discs should be applied at a 15 to 30-degree angle to the material to prevent the grinder from pulling away from you.

- Don’t apply the angle grinder to any material until it’s up to full speed to avoid grabbing and kickback.

- Ensure the disc has completely stopped turning before putting it down or moving it.

- There is a lot of vibration involved with grinding, so take periodic breaks to prevent hand and arm fatigue.

Angle Grinder Safety Innovations

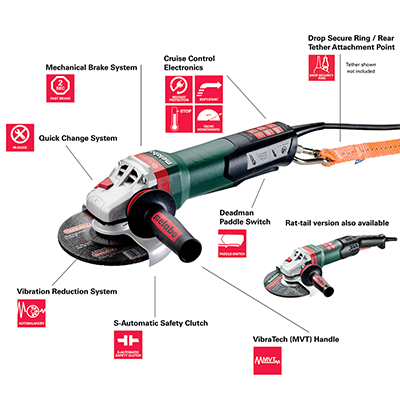

Angle grinder technology has come a long way over the years. The design of grinders has become lighter, more ergonomic and powerful, and most of all, safer. Some of the top brands in the industry are creating advances in safety technology year after year to ensure you’re getting the safest possible tool to work with.

Makita was the first company to release angle grinders with non-removable guards. The guards also feature quick-guard rotation, so they can be adjusted without a tool to fit any grinding application. That technology has been implemented in many of their grinders.

Electronic clutch protection, anti-restart protection, and advanced brake technology are other safety additions implemented in angle grinders from Metabo, Makita, DEWALT, and Milwaukee Tool.

The biggest advancement across the board is the brake technology in grinders, with some being able to stop a thin cutting wheel in under 1 second and the majority of other discs stopping in under 2 seconds. This greatly reduces the chance of a kickback or loss of control of the tool. Electronic clutch protection minimizes kickback when a disk jams during a cut. Anti-restart protection prevents the motor from starting if a battery is inserted while the power switch is locked on. Some angle grinders feature paddle switches that will stop the machine if not pressed. This reduces the chance of the tool coming in contact with any part of your body or dancing across the floor if the power goes out or the tool falls out of your hand.

Shop angle grinders from top brands such as Milwaukee, Makita, DEWALT, Metabo, Bosch, and more at Acme Tools.