There are many different ways to categorize reciprocating (piston-type) air compressors: horsepower, CFM output, frame type, tank size, and so on. All of those are pretty self-explanatory. However, an often overlooked and misunderstood category is the number of compression stages. Your options here are either single-stage or two-stage, and knowing the difference between them can help ensure you’ll find the suitable air compressor for the job. The following post will explain the difference between single-stage and two-stage air compressors, outlining recommended scenarios for each.

It’s All About The Pump

The number of compression stages is determined by the pump’s configuration. Air compressor pumps come in a wide variety of shapes, sizes, and piston configurations, so to avoid muddying the waters, this post will focus on single- and two-stage belt-driven pumps with two pistons.

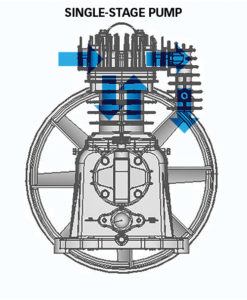

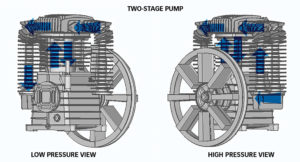

As you’ve likely gleaned from the introductory paragraph, the most significant difference between the two types is that single-stage pumps compressed air once, and two-stage pumps compressed air twice. The most noticeable difference is the shape of the cylinder, which is where the pistons are located. Both pistons are the same size in a single-stage pump, so both sides of the cylinder have the exact physical dimensions. A two-stage pump has one low-pressure (large) piston and one high-pressure (slight) piston. In this type of setup, one side of the cylinder is visibly more significant than the other.

Let’s look at the steps that the air goes through as it travels through the pump and to the tank:

Single-Stage

As the pistons draw down, air is sucked in through the filter element and past the intake valves into the cylinder. While the crankshaft rotates and the pistons are pushed upward, the air gets compressed as it is forced up through the exhaust valves. From there, it travels through the discharge tube and check valve, down into the tank, where it will stay until the user demands air.

Two-Stage

As the low-pressure (more significant) piston draws down, the air is sucked in through the filter element and past the intake valve into the cylinder. While the crankshaft rotates and the low-pressure piston is pushed upward, the air gets compressed for the first time as it is forced up through the low-pressure exhaust valve. From there, the air travels through an intercooler to the high-pressure side of the pump, where it is drawn into the cylinder and compressed a second time. It then travels through the discharge tube and checks the valve down into the tank, where it will stay until the user demands air.

Each One Has Its Place.

Generally, two-stage air compressors are more efficient, run more relaxed, and deliver more CFM than their single-stage counterparts. While that may seem like a convincing argument against single-stage models, realizing that they also have advantages is essential. Single-stage compressors generally cost less and weigh less; electric models draw fewer amps. Which type is right for you depends on the work you do. Single-stage models are great for individual tradesmen or small crews framing, sheathing, roofing, or trimming. For larger construction crews or applications requiring large amounts of air over extended periods, two-stage compressors are the go-to option.

This post was written by Corey Nampel, Marketing Manager of ROLAIR. ROLAIR Compressors have been serving the needs of the residential contractor since 1959. To see more of their posts, visit the Zero Sick Days blog.