When you’re working with your feet off the ground, even an innocent tape measure that slips from your grasp or slides off your belt becomes a dangerous meteor plummeting to the jobsite below. After all, any object –however small – gains force as it accelerates downward as a result of gravity. Tethering tools will prevent unwanted injuries.

With that in mind, workers should be sure to use safe O@H (Objects at Heights) management practices when they are: working six feet above ground level; elevated relative to other personnel or sensitive objects; raising and lowering equipment to and from elevated areas; or as otherwise determined by a safety manager.

Abide by the Three T’s of dropped object safety

- Trap: Create a connection point on tools that do not have one built-in.

- Tether: Secure an object to a worker or other anchor point to prevent the object from falling.

- Top: Cover buckets, pouches and other containers while at heights to avoid spilling their contents if tipped or inverted.

Create a Trap

Determining how workers should trap, tether or top will depend on the tools they need to bring with them for work at heights. Before workers can choose the right safety solution, however, they must pick the right tools. Use tools with inherent captive connection points whenever possible. If a tool doesn’t have a secure connection point for tethering, then a worker can create one with a retrofit attachment point, aka a “Trap.” Other best practices for tool selection should also be considered:

- Tools with multiple parts should have systems to prevent the separation of parts (e.g., sockets should lock into wrenches).

- Hammers and other striking tools should have steel or composite shafts (head-locking mechanism preferred).

- Choose tools with non-slip handles whenever possible. These grips should be securely fasted to or inherent to the handle.

As workers will find, most tools lack a convenient connection point. Keeping an updated Tool Inventory Log to refer back to can help tool crib managers know what retrofit solutions go on what tools and document tool weights to compare to the maximum capacity of a tethering system.

Tethering Tools Can Prevent Injury

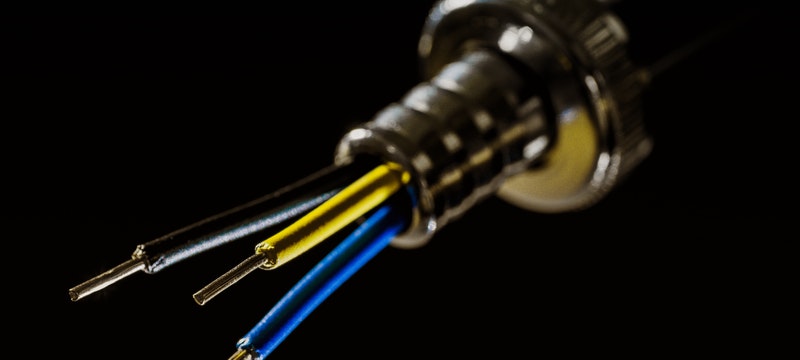

After a worker’s tools are outfitted with connection points, there are important best practices for tethering to consider. The Tether prevents the object from falling at all or limits the fall if a tool is dropped. Tethers aren’t just for tools, but can also be used for PPE, communication equipment like cell phones and radios, and any other equipment or materials a worker needs for at-heights jobs. When choosing the right tool lanyard, weigh these critical factors:

- Capacity: The weight of the tool vs. the capacity of the solution. You must know the weight of the tool to be tethered.

- Connectors: Type, material and function of connection needed for tool and anchor point.

- Body: Material and style of lanyard

Anchor tool lanyards to a static rated anchor point if and when possible but certainly when the tool weighs more than 10lbs (4.5kg). Tools weighing less than 10lbs (4.5kg) may be anchored to the body if so desired but a quality shock-absorbing tool lanyard is recommended. If anchoring tool lanyards to the body don’t attach a lanyard’s connector to a D-ring actively being used for fall protection or positioning and don’t connect to breakaway connections, like lanyard keepers.

Prevent Spills with a Top

One of the main culprits of dropped objects at heights is small parts and hardware that can’t be tethered. Workers who need these parts should bring them to heights in a spill-proof and secure bucket, pouch or other container. For workers who already have their hands full at heights, products like topped parts pouches that don’t require zipping, buckling or string pulling can be a lifesaver.

This blog post was created in cooperation with Ergodyne, a producer of Tenacious Work Gear*. Acme Tools is a proud distributor of Ergodyne products and supports their blog.