In our 75+ years of experience in the power tools and construction industries, we’ve learned a thing or two about power tools. Now, we’re sharing our favorite power tools, tricks, tips, and lifehacks to help you make your job or hobby easier, more accurate, and more efficient.

A clamp attached to your table saw’s rail makes a great fence stop so you can make accurate, repeatable cuts. This, of course, only works when you move the fence closer to the blade and then need to return it back to its original position.

A clamp attached to your table saw’s rail makes a great fence stop so you can make accurate, repeatable cuts. This, of course, only works when you move the fence closer to the blade and then need to return it back to its original position. It’s a good safety practice to unplug tools before changing blades and router bits. As a reminder, use a permanent marker to write “unplug” on the wrenches used to change bits and blades. What do you write on wrenches and push sticks to stay safe?

It’s a good safety practice to unplug tools before changing blades and router bits. As a reminder, use a permanent marker to write “unplug” on the wrenches used to change bits and blades. What do you write on wrenches and push sticks to stay safe? Cut lines can be difficult to follow at times. Pencils and Pens don't write on finished metal very well and markers leave a wide line and bleed into soft materials so if this sounds familiar, grab a piece of duct tape or painters tape and use it to create your line. The line will be easier to see and much easier to follow.

Cut lines can be difficult to follow at times. Pencils and Pens don't write on finished metal very well and markers leave a wide line and bleed into soft materials so if this sounds familiar, grab a piece of duct tape or painters tape and use it to create your line. The line will be easier to see and much easier to follow. If you don’t have a small drill bit handy, simply clip the head off a small nail. Then, chuck this headless nail into your drill. It’s amazing how well the nail works in creating a nice, clean hole. This also works great for pre-drilling hardwood trim if you are not using an air nailer.

If you don’t have a small drill bit handy, simply clip the head off a small nail. Then, chuck this headless nail into your drill. It’s amazing how well the nail works in creating a nice, clean hole. This also works great for pre-drilling hardwood trim if you are not using an air nailer. If you need to countersink a hole on a workpiece where you don't have access for your drill just start with a pilot hole and insert the countersink into the hole and then chuck the flute end of the bit into your drill and pull the countersink into the piece. It might not be pretty but it sure beats taking the drawer apart.

If you need to countersink a hole on a workpiece where you don't have access for your drill just start with a pilot hole and insert the countersink into the hole and then chuck the flute end of the bit into your drill and pull the countersink into the piece. It might not be pretty but it sure beats taking the drawer apart. The combination of an eye screw and drill are a powerful force. Not only will an eye screw help you drill straight but it will also assist in driving in screw hooks. Drill a pilot hole, start the threads by hand, and then chuck your eye screw into your drill and slide it over the top of the hook. Slow and steady is the best action for this. What if you need to insert an eye screw? This time you chuck the screw hook into your drill. Quick and Easy!

The combination of an eye screw and drill are a powerful force. Not only will an eye screw help you drill straight but it will also assist in driving in screw hooks. Drill a pilot hole, start the threads by hand, and then chuck your eye screw into your drill and slide it over the top of the hook. Slow and steady is the best action for this. What if you need to insert an eye screw? This time you chuck the screw hook into your drill. Quick and Easy! Crown molding may slip away from the miter saw fence when it is placed on edge at an angle. To make a non-slip surface on the miter saw table, stick pieces of sandpaper onto your saw’s table using double-sided tape. When applying the sandpaper, leave room for the blade to pass by, and make sure you can still turn the table if needed.

Crown molding may slip away from the miter saw fence when it is placed on edge at an angle. To make a non-slip surface on the miter saw table, stick pieces of sandpaper onto your saw’s table using double-sided tape. When applying the sandpaper, leave room for the blade to pass by, and make sure you can still turn the table if needed. When using a hole saw, it’s common for sawdust to stick between the teeth and bog down the cut. Eliminate this with a relief hole that allows sawdust to fall through. You’ll be amazed how much easier and cleaner the cut will be.

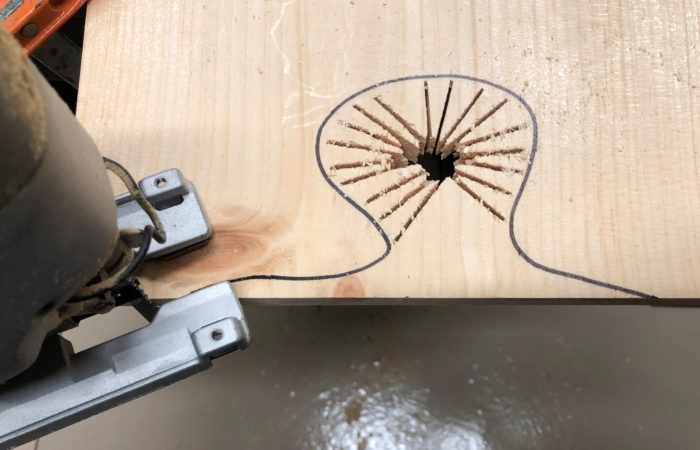

When using a hole saw, it’s common for sawdust to stick between the teeth and bog down the cut. Eliminate this with a relief hole that allows sawdust to fall through. You’ll be amazed how much easier and cleaner the cut will be. Cutting tight curves can be challenging even when using a thin jigsaw blade. A series of relief cuts can help solve the problem. Drill a starter hole on the waste side of the curve, and then make relief cuts that almost touch your line. You’ll be surprise how much quicker and more accurate the cut will be.

Cutting tight curves can be challenging even when using a thin jigsaw blade. A series of relief cuts can help solve the problem. Drill a starter hole on the waste side of the curve, and then make relief cuts that almost touch your line. You’ll be surprise how much quicker and more accurate the cut will be. Tired of waiting for your orbit sander to stop vibrating after it’s turned off? If you put it down too soon, you’ll create swirl marks on your project or workbench and the vibrations may cause the tool to tumble to the floor. Instead, park it on a piece of carpet that’s been glued to a board. And, if you need to put the sander down for just a short period of time, you don’t even have to turn in off.

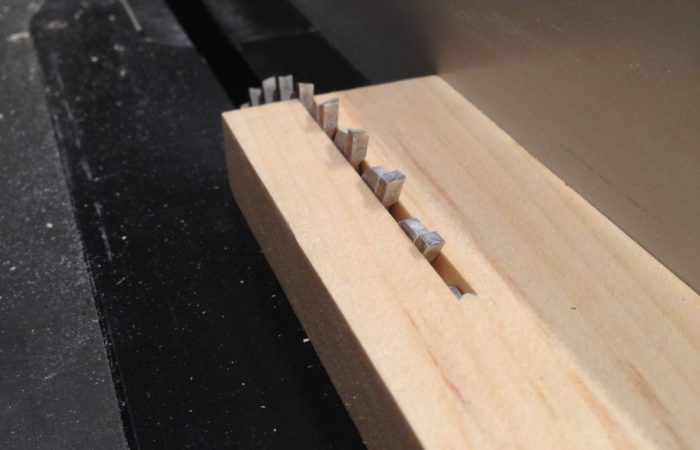

Tired of waiting for your orbit sander to stop vibrating after it’s turned off? If you put it down too soon, you’ll create swirl marks on your project or workbench and the vibrations may cause the tool to tumble to the floor. Instead, park it on a piece of carpet that’s been glued to a board. And, if you need to put the sander down for just a short period of time, you don’t even have to turn in off. Remembering which dado blades and shims combine to make a certain size can be difficult. Instead of constant trial and error, number your set. When the desired size is obtained make note of which blades made up the cut and write it down in a safe area. When you need to make that cut in the future just grab the corresponding blades.

Remembering which dado blades and shims combine to make a certain size can be difficult. Instead of constant trial and error, number your set. When the desired size is obtained make note of which blades made up the cut and write it down in a safe area. When you need to make that cut in the future just grab the corresponding blades. When ripping long, narrow boards, cut the stock halfway down its length, then flip it over and cut the other half. This keeps your fingers away from the blade and you don’t have to negotiate a push stick on the narrow stock. Just remember to keep the same side of the stock against the fence for the second cut as you did for the first.

When ripping long, narrow boards, cut the stock halfway down its length, then flip it over and cut the other half. This keeps your fingers away from the blade and you don’t have to negotiate a push stick on the narrow stock. Just remember to keep the same side of the stock against the fence for the second cut as you did for the first. If you find yourself needing a replacement knob remember this trick. Fill a plastic bottle cap with epoxy and place an appropriate size machine screw into the middle of the cap allowing the epoxy to hold the screw. Once the epoxy cures you are all set.

If you find yourself needing a replacement knob remember this trick. Fill a plastic bottle cap with epoxy and place an appropriate size machine screw into the middle of the cap allowing the epoxy to hold the screw. Once the epoxy cures you are all set. Pneumatic nailers can leave small dents and marks on your workpiece, especially if the finish has already been applied. To eliminate this problem, cut a piece of plastic from a milk jug and use it as a bumper guard to protect it. Bingo! The nail will easily shoot though the plastic and set into the beautiful, un-marred wood.

Pneumatic nailers can leave small dents and marks on your workpiece, especially if the finish has already been applied. To eliminate this problem, cut a piece of plastic from a milk jug and use it as a bumper guard to protect it. Bingo! The nail will easily shoot though the plastic and set into the beautiful, un-marred wood. Looking for a "Cool" tip to get your spindle sander sleeves on and off the drum easier? About an hour before you are going to use the sander place the rubber drum into the freezer. The cold temperature will shrink the drum just enough to make installing the sleeve easy and when it warms up it will expand making a tight friction fit.

Looking for a "Cool" tip to get your spindle sander sleeves on and off the drum easier? About an hour before you are going to use the sander place the rubber drum into the freezer. The cold temperature will shrink the drum just enough to make installing the sleeve easy and when it warms up it will expand making a tight friction fit. Ripping narrow pieces on the table saw can be tricky business. When the set-up becomes too narrow for a push-stick, use a homemade push-board instead. Cut a ½” notch in a board that will give you complete control of your workpiece as you make the cut.

Ripping narrow pieces on the table saw can be tricky business. When the set-up becomes too narrow for a push-stick, use a homemade push-board instead. Cut a ½” notch in a board that will give you complete control of your workpiece as you make the cut. Is the base of your saw not sliding over your material easily? Don't get frustrated, take a walk into the kitchen and grab some wax paper. Rub it over the bottom side of the base that needs to “glide” over surfaces. A small amount of wax from the paper will stay on the tool and will help reduce friction.

Is the base of your saw not sliding over your material easily? Don't get frustrated, take a walk into the kitchen and grab some wax paper. Rub it over the bottom side of the base that needs to “glide” over surfaces. A small amount of wax from the paper will stay on the tool and will help reduce friction. Sure you can use tape on the bit as a guide, but the tape tends to move up or tear and it doesn't prevent you from drilling to deep. To make a great depth gauge for your drill, take the bit you’ll be using and drill a hole through a short section of dowel. The dowel’s length should leave the right amount of bit protruding from the dowel to give the right hole depth. Slight adjustments can be made by changing placement of the bit in the chuck.

Sure you can use tape on the bit as a guide, but the tape tends to move up or tear and it doesn't prevent you from drilling to deep. To make a great depth gauge for your drill, take the bit you’ll be using and drill a hole through a short section of dowel. The dowel’s length should leave the right amount of bit protruding from the dowel to give the right hole depth. Slight adjustments can be made by changing placement of the bit in the chuck. Here’s a nifty way to keep your paint sprayer nozzle free of any dried residue and ready for accurate spaying. After use, clean the nozzle and then store it the sprayer’s container submerged in a little paint thinner if you were using an oil based finish or water if you were using a latex paint.

Here’s a nifty way to keep your paint sprayer nozzle free of any dried residue and ready for accurate spaying. After use, clean the nozzle and then store it the sprayer’s container submerged in a little paint thinner if you were using an oil based finish or water if you were using a latex paint. Plastic pie keepers are great to use when giving your saw blades a scrub-down. They keep the blade cleaner from splashing out, and the soft sides don’t damage the blade’s teeth. They are very inexpensive, and you can often find them at a “dollar” store.

Plastic pie keepers are great to use when giving your saw blades a scrub-down. They keep the blade cleaner from splashing out, and the soft sides don’t damage the blade’s teeth. They are very inexpensive, and you can often find them at a “dollar” store. If you can’t get a big or hard-to-reach workpiece to an oscillating spindle sander, have no fear! Just remove the drum along with the abrasive sleeve from your spindle sander, then chuck it into a drill with the help of a bolt, two washers and a nut. Bam! Crisis averted!

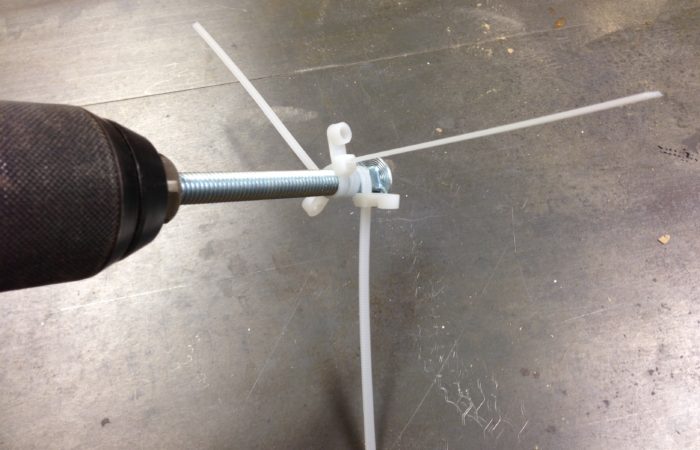

If you can’t get a big or hard-to-reach workpiece to an oscillating spindle sander, have no fear! Just remove the drum along with the abrasive sleeve from your spindle sander, then chuck it into a drill with the help of a bolt, two washers and a nut. Bam! Crisis averted! The ingredients in paint typically separate over time, so stir the can before you start to paint and every so often during the task. Sure, you can use a wooden stirrer, but for added efficiency and more fun, attach a few zip ties to a long bolt or screw, chuck it into your drill, and give the paint a whirl. Voila! You’re ready to paint your masterpiece and had some fun while doing it.

The ingredients in paint typically separate over time, so stir the can before you start to paint and every so often during the task. Sure, you can use a wooden stirrer, but for added efficiency and more fun, attach a few zip ties to a long bolt or screw, chuck it into your drill, and give the paint a whirl. Voila! You’re ready to paint your masterpiece and had some fun while doing it. Sometimes it’s hard to use to a backer board to reduce blow-out and splintering, such as when drilling into panels. In these cases, drill half way through from both directions to produce a hole with clean edges. Start by drilling a small pilot hole all the way through the workpiece to help guide your larger bit.

Sometimes it’s hard to use to a backer board to reduce blow-out and splintering, such as when drilling into panels. In these cases, drill half way through from both directions to produce a hole with clean edges. Start by drilling a small pilot hole all the way through the workpiece to help guide your larger bit. We all love spending time with our children and no matter if they are in the shop with you or outside their safety is a major concern. By slipping a key ring though one of the holes in your tool’s plug it will prevent them from plugging it in when not under your watchful eye. Once they have learned the proper use of the tool feel free to remove the rings. Their safety is up to you.

We all love spending time with our children and no matter if they are in the shop with you or outside their safety is a major concern. By slipping a key ring though one of the holes in your tool’s plug it will prevent them from plugging it in when not under your watchful eye. Once they have learned the proper use of the tool feel free to remove the rings. Their safety is up to you. Metal shavings can wreak havoc with dust collection systems and vacs. To corral these little buggers when using a drill press, put a backer block in the middle of a shallow pan. The thickness of the backer block should be the same as the depth of the pan. When finished drilling just dispose of the shavings into the garbage. We also find it best not us use a pan straight from the kitchen or a glass plate.

Metal shavings can wreak havoc with dust collection systems and vacs. To corral these little buggers when using a drill press, put a backer block in the middle of a shallow pan. The thickness of the backer block should be the same as the depth of the pan. When finished drilling just dispose of the shavings into the garbage. We also find it best not us use a pan straight from the kitchen or a glass plate. When starting a project, make a trial cut with a piece of scrap wood. Use a try square to check that the saw is cutting square. This is especially important if using a miter saw that had been transported and possibly bumped along the way. It’s also a quick way to test the accuracy of your tablesaw’s miter gauge. In either case, make adjustments to the saw or miter gauge if the test cut isn’t square. Once the adjustments have been made make another test cut and recheck. Continue this process until the saw has been completely adjusted.

When starting a project, make a trial cut with a piece of scrap wood. Use a try square to check that the saw is cutting square. This is especially important if using a miter saw that had been transported and possibly bumped along the way. It’s also a quick way to test the accuracy of your tablesaw’s miter gauge. In either case, make adjustments to the saw or miter gauge if the test cut isn’t square. Once the adjustments have been made make another test cut and recheck. Continue this process until the saw has been completely adjusted. It’s often hard to tell router bits apart from each other. Hmmmm…is that a 45-degree chamfer bit or a 30-degree? Make it easier and quicker to select the right bits by marking them with a permanent marker. Write on the bottom where there’s plenty of room and the ink is less likely to be worn off.

It’s often hard to tell router bits apart from each other. Hmmmm…is that a 45-degree chamfer bit or a 30-degree? Make it easier and quicker to select the right bits by marking them with a permanent marker. Write on the bottom where there’s plenty of room and the ink is less likely to be worn off. When the bit suddenly breaks through the material being drilled into, the drill’s chuck can uncontrollably slam into the workpiece, causing a dent or scratch. When drilling into delicate materials protect the surface by securing a piece a felt at the base of the bit. A rotary tool’s felt polishing wheel or a furniture leg felt pad makes a perfect drill bumper cushion.

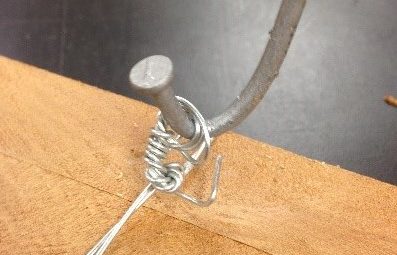

When the bit suddenly breaks through the material being drilled into, the drill’s chuck can uncontrollably slam into the workpiece, causing a dent or scratch. When drilling into delicate materials protect the surface by securing a piece a felt at the base of the bit. A rotary tool’s felt polishing wheel or a furniture leg felt pad makes a perfect drill bumper cushion. Have you ever found yourself struggling to twist wire for a picture frame or when securing some wire to a fence post? Here is how a couple of loops and a nail can come to your rescue. Bend the nail, chuck it into your drill, slide it through the wire loops, and tap the drill’s trigger a few times. Boom! You have an ultra-efficient way to twist wire.

Have you ever found yourself struggling to twist wire for a picture frame or when securing some wire to a fence post? Here is how a couple of loops and a nail can come to your rescue. Bend the nail, chuck it into your drill, slide it through the wire loops, and tap the drill’s trigger a few times. Boom! You have an ultra-efficient way to twist wire. When using a belt sander on a small workpiece, clamp a scrap of wood behind the workpiece. This will keep your sander from launching the workpiece into your shop, or worse yet, into your stomach, and because clamps are used to hold the scrap down you don’t need them to hold your project. This will allow you to sand the entire face of the workpiece at the same time. The scrap should not be thicker than the workpiece so that sander has access to its whole length.

When using a belt sander on a small workpiece, clamp a scrap of wood behind the workpiece. This will keep your sander from launching the workpiece into your shop, or worse yet, into your stomach, and because clamps are used to hold the scrap down you don’t need them to hold your project. This will allow you to sand the entire face of the workpiece at the same time. The scrap should not be thicker than the workpiece so that sander has access to its whole length. When cutting laminate flooring with a miter saw, place the good side up and use duct tape to minimize chipping. (If you use white duct tape, the cut lines are super easy to see.) Also, use a blade specifically made for laminate material, or at least, use a blade with a tooth count of 100 or more.

When cutting laminate flooring with a miter saw, place the good side up and use duct tape to minimize chipping. (If you use white duct tape, the cut lines are super easy to see.) Also, use a blade specifically made for laminate material, or at least, use a blade with a tooth count of 100 or more. Are you sick of cheap hex wrenches included with furniture stripping screws, wearing out fast, and being slow? Most ready-to-assemble furniture uses 1/4″ hex bolts so here is a trick to keep you up and running and will speed assembly right along. Take a 1/4″ hex screwdriver bit that most Impact Drivers use and chuck it into your drill backwards. The drill will give you all the speed you need but will also increase the torque, so be careful.

Are you sick of cheap hex wrenches included with furniture stripping screws, wearing out fast, and being slow? Most ready-to-assemble furniture uses 1/4″ hex bolts so here is a trick to keep you up and running and will speed assembly right along. Take a 1/4″ hex screwdriver bit that most Impact Drivers use and chuck it into your drill backwards. The drill will give you all the speed you need but will also increase the torque, so be careful. When cutting plywood, make sure the good side is down. If you need two good sides, use a straightedge to score the plywood with a sharp utility knife, cutting through the top layer of veneer. Then, position the saw blade on the scrap side of the score line when making the final cut.

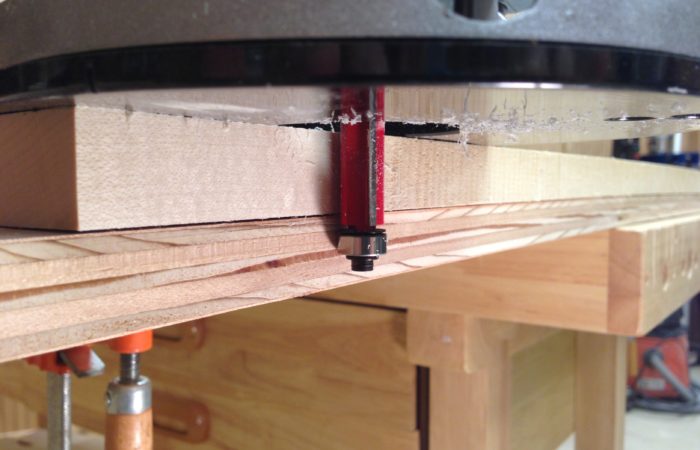

When cutting plywood, make sure the good side is down. If you need two good sides, use a straightedge to score the plywood with a sharp utility knife, cutting through the top layer of veneer. Then, position the saw blade on the scrap side of the score line when making the final cut. No jointer, not a problem! Grab your router instead. To put a straight, smooth edge along a board’s length, a jointer will do the trick. But if you don’t have a jointer handy, you can use your router and a straight bit with a bearing on the bottom. Clamp the work piece to plywood that has a factory-produced flat edge. Your workpiece should be several inches shorter than the plywood and its edge should hand over the plywood slightly as shown. When routing, the bearing will follow the straight plywood edge, while cutting the work piece straight and smooth.

No jointer, not a problem! Grab your router instead. To put a straight, smooth edge along a board’s length, a jointer will do the trick. But if you don’t have a jointer handy, you can use your router and a straight bit with a bearing on the bottom. Clamp the work piece to plywood that has a factory-produced flat edge. Your workpiece should be several inches shorter than the plywood and its edge should hand over the plywood slightly as shown. When routing, the bearing will follow the straight plywood edge, while cutting the work piece straight and smooth. Drilling in reverse can actually produce the cleanest hole. When using a brad point bit, start with the drill in reverse for a few revolutions to score the edges of the hole. Then, change the bit direction and drill your hole. It will produce a crisp clean hole every time.

Drilling in reverse can actually produce the cleanest hole. When using a brad point bit, start with the drill in reverse for a few revolutions to score the edges of the hole. Then, change the bit direction and drill your hole. It will produce a crisp clean hole every time. A very easy and accurate way to mark angles on your stock is to use your table saw’s miter gauge. Simply set the angle you want on your miter gauge and then place it upside down onto your work piece. The shoulder of the miter gauge will be flush to the side of your work piece and the T-Slot will be set at your angle and will allow you to trace it. Quick and easy, and most likely you received it free with the purchase of a different tool.

A very easy and accurate way to mark angles on your stock is to use your table saw’s miter gauge. Simply set the angle you want on your miter gauge and then place it upside down onto your work piece. The shoulder of the miter gauge will be flush to the side of your work piece and the T-Slot will be set at your angle and will allow you to trace it. Quick and easy, and most likely you received it free with the purchase of a different tool.

Also, check out our two complementary blog posts below:

6 Comments

Paul L.

April 19, 2018 at 7:59 pmI’ve used an old 1-1/4″ paddle spade bit… just gotta watch you don’t drill through the can!

I could grind the tip off, I imagine.

Dan Miester

July 16, 2020 at 12:07 pmI ordered a toughsystem extra large box model DSW t 08400 I am in a major rush for this item. I cannot use my toughsystem set up without this box. Please contact me in regards to when I can get my order. Thank you, Dan miester

Acme Tools

July 16, 2020 at 1:21 pmHi Dan, Thank you for your comment. We have passed your email address and comment onto our Customer Support department and they should be contacting you shortly.

Thank you,

Acme Tools

KEVIN BENAK

August 21, 2020 at 12:10 pmLOOKING FOR A CORDLESS COMPRESSOR FOR INFLATION OF WATER TUBES, BIKE TIRES, AND SMALL AIR TOOLS FOR HOME PROJECTS WITH AIR TOOLS, NAIL GUNS ETC.

Acme Tools

August 24, 2020 at 8:16 amHi Kevin. Thank you for your inquiry. Currently we have a couple very good options for you. The Milwaukee 2840-20 has been very good cordless option for light inflation and air tools that have low cfm requirements.

Thank you,

Acme Tools

Williams

May 29, 2024 at 7:27 pmA clamp is definitely a great money-saver for when you cut lumber. There’s nothing quite as frustrating as getting pieces from a lumberyard and then botching the cut.