An angle grinder is a much more versatile power tool than you might think at first glance and can be found in almost any trade industry, from construction to metalworking and even woodworking.

What makes them so versatile is the many different angle grinder wheels and discs that can be used with them, such as grinding wheels, cut-off discs, flap discs, and more. With these different wheels, you can do everything from cutting metal sheets to removing paint.

Our trusty angle grinder disc guide will explain the different types and their uses. Afterward, you’ll better understand how each works and which one you need to accomplish a specific task.

Grinding Wheels

Grinding wheels, sometimes called grit discs, are easily the most recognizable and most popular discs due to their general-purpose nature. They are available in several different sizes up to 10 inches and varying degrees of thickness to tackle specific projects.

Grinding wheels come in varying grit levels. Lower grit numbers are coarser, while higher-numbered grit is less coarse. Low-grit grinding wheels are perfect for rough, quick work where you aren’t as worried about the finished look of your project. If you want a smoother finish, use a high-grit grinding wheel.

A grinding wheel’s main use is removing excess material from a project’s surface. Other uses include preparing metal for welding, cleaning up cuts, and several others, which is why a grinding wheel is considered an all-purpose disc.

Cut-Off Wheels

Cut-off wheels look similar to grinding wheels but serve a much different purpose. The distinguishing feature of a cut-off wheel is its thin design, which allows it to make more precise cuts in metal bars and sheets. Due to their thin design, these discs can be dangerous, so wear the proper protective gear.

Wheels come in different thicknesses, each with its own pros and cons. The thinner the disc, the quicker cuts can be made, but the more brittle they’ll be. A thicker disc is more substantial and less likely to warp during a cut. If the disc is bent in an odd direction, it will shatter, sending shards around the room that could prove hazardous or lead to serious injury.

Cut-off wheels are primarily used for cutting different metal pieces, including metal bars, tubes, and small pieces of sheet metal or plates. They can also be used to cut out welds or shorten too-long bolts.

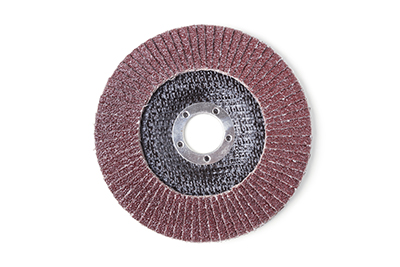

Flap Wheels

A flap wheel doesn’t look like one, but it works very similarly to a traditional grinding wheel. It separates itself by providing a much finer finish to your project and is commonly used for finishing work. The disc is made of overlapping abrasive sheets called flaps, hence the name. There are several grit options with the same method: the higher the number of grit, the smoother the finish.

You’ll usually switch to a flap wheel after a surface has already been worked on with a grinding wheel. As the flaps wear away, new grit is exposed, so the wheel will continuously operate at peak condition until all the grit is gone. They work well for removing minor imperfections, such as burrs or scratches, and removing rust or polishing a surface. These angle grinder wheels are commonly found in autobody shops and metalworking and fabrication trades.

Wire Wheels

Wire wheels have varying styles with different purposes in mind, but generally, they all have the same general makeup of wires protruding from a circular base. They feature thick, twisted bristles, which are more abrasive for faster, more accessible work, or thinner, straighter bristles, which are less abrasive for finer, precision jobs.

These angle grinder attachments are used to quickly remove rust or polish hard metal. They can be used on softer materials but can lead to scratches on the surface, so proceed with caution. Wire wheels are also a good solution for removing paint from a surface.

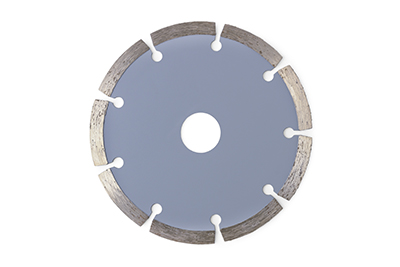

Diamond Cutting Wheels

Diamond blades are typically the most rigid blades on the market, and diamond cutting wheels are no different. The edges are embedded with diamond grits. Due to their hardened design, they tend to last longer than other blades. The higher the cutting rim, the longer the disc will last, and the more durable it is.

You can work quickly and easily on the majority of applications. Diamond discs can be used on some of the toughest materials, such as masonry or stone, in both wet and dry cutting operations.

Paint Stripping Wheels

Paint stripping wheels, sometimes called strip discs, are a common alternative to wire wheels when removing paint from a surface. They work best when working on materials that are a little more delicate, such as soft metals, wood, or fiberglass, as they won’t scratch the material.

The poly-fiber material used in strip discs makes them better suited for working on softer surfaces without damaging their surface. They also can be used to remove epoxy or other residues.

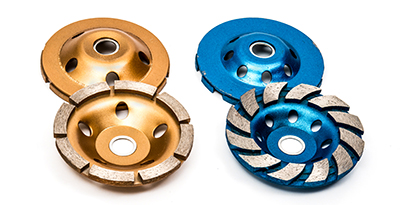

Concrete Grinding Wheels

Sometimes, you may need to remove concrete from your surface or polish concrete entirely, and there’s a grinding wheel attachment for that job. Concrete grinding wheels come in many shapes and forms. They are made of solid materials, such as fiberglass and other abrasive materials, to handle the tough structure of concrete.

Concrete grinding wheels can handle many other materials, such as masonry, granite, marble, stone, and other hard materials. Their makeup allows these discs to be long-lasting over time, but eventually, they’ll wear down, so you’ll want to replace them when they begin to chip.

As always, be sure to follow proper safety procedures when using an angle grinder and wear any applicable personal protective equipment. A vital thing to consider is that the disc size and RPM of the angle grinder need to match to avoid damage to the disc, which can lead to injury. The top manufacturers of power tools are developing new safety technologies every day to make working with your angle grinder safer for you and those around you.

Shop all of your angle grinder wheel attachment needs from some of the top brands, such as Milwaukee Tool, DEWALT, Diablo Tools, Makita, Bosch, and more, at Acme Tools.