You now own one of the most essential tools for the carpenter, craftsman and weekend warrior. The circular saw will allow you to easily make straight, clean, precise cuts through a variety of materials. If you’ve been using a hand saw for this operation in the past, you are in for a real treat!

While the circular saw is easy to use, here’s some basic information you should know to achieve the best results safely.

Dress for Safety.

Don’t wear loose clothing or dangling jewelry. Wear eye protection and a dust mask to block the flying debris and sawdust. And, since the tool operates at a high pitch, wear proper ear protection.

Don’t wear loose clothing or dangling jewelry. Wear eye protection and a dust mask to block the flying debris and sawdust. And, since the tool operates at a high pitch, wear proper ear protection.

Use the Right Blade.

Your saw probably came with a standard blade that’s good for cutting wood studs. You may want to consider replacing it with a blade that’s best for your type of work. For example, you can choose from rip-cut blades, crosscut blades, framing blades, plywood blades, and thin-kerf blades. If you use your saw for general woodworking, a combination blade would be a good choice. Combination blades are designed to perform well while making both cross and rip cuts. As for blade size, use the size to match your saw, e.g., use a 7 ¼” blade with a 7 ¼” saw.

Your saw probably came with a standard blade that’s good for cutting wood studs. You may want to consider replacing it with a blade that’s best for your type of work. For example, you can choose from rip-cut blades, crosscut blades, framing blades, plywood blades, and thin-kerf blades. If you use your saw for general woodworking, a combination blade would be a good choice. Combination blades are designed to perform well while making both cross and rip cuts. As for blade size, use the size to match your saw, e.g., use a 7 ¼” blade with a 7 ¼” saw.

Set the Blade Depth and Bevel Angle

Refer to the tool’s manual for information on adjusting the settings on your saw. The saw should be set so that only ¼” of the blade extends below the bottom of your workpiece. A blade that extends beyond this will force the saw to work harder. Also, it is more dangerous to have more teeth exposed.

Refer to the tool’s manual for information on adjusting the settings on your saw. The saw should be set so that only ¼” of the blade extends below the bottom of your workpiece. A blade that extends beyond this will force the saw to work harder. Also, it is more dangerous to have more teeth exposed.

If making a bevel cut, adjust the setting to the desired angle. Whether making a bevel cut or not, always make sure that the bevel adjustment knob is securely locked in place before cutting.

Avoid Binding

During rough cuts (such as cutting wood studs), the end of the workpiece should be free to fall away after the cut. However, since the falling piece can produce splinters, the cut-off piece should be supported when making finer cuts. Just make sure that the waste piece doesn’t pinch the blade.

During rough cuts (such as cutting wood studs), the end of the workpiece should be free to fall away after the cut. However, since the falling piece can produce splinters, the cut-off piece should be supported when making finer cuts. Just make sure that the waste piece doesn’t pinch the blade.

Make A Controlled Cut

First, make sure there’s enough space in the work area for you to complete the entire cut.

First, make sure there’s enough space in the work area for you to complete the entire cut.

Then, line up the saw’s guide notches with the cutting line you drew on the workpiece. As a matter of personal preference, some people like to use the blade itself to line up the cut, instead of the guide notches. Either way, you’ll want to stay slightly to the “waste side” of the line to allow for the width of the blade.

When ready to cut, pull the saw’s trigger and wait for the blade to get up to speed. Then, push the saw through the workpiece, while keeping the blade on the cut line. It’s important to keep the base of the saw flat on your workpiece through the whole cut.

How hard and fast should you push the saw? Push the saw with enough force to keep it moving smoothly through the workpiece. If you hear the motor getting bogged down, or feel the resistance of a binding blade, slow your rate of speed.

Fix A Wandering Cut

Beginners often have trouble keeping the blade on their cut line when cutting. If the blade drifts off the line, don’t try to force the blade back to the line. Instead, release the trigger and wait for the blade to stop spinning. Put the saw back to where the cut was still on the line and start cutting again from that point.

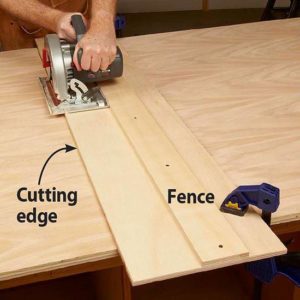

Use Guides for Spot-On Results

If accuracy is important, use a guide to keep the saw traveling in a straight line as you cut. You can simply clamp a straight edge to the workpiece to guide your saw. But, for best results, consider using a precision guide complete with adjustments and clamps that will give you much more accuracy and speed of set up.

If accuracy is important, use a guide to keep the saw traveling in a straight line as you cut. You can simply clamp a straight edge to the workpiece to guide your saw. But, for best results, consider using a precision guide complete with adjustments and clamps that will give you much more accuracy and speed of set up.

Good luck with your new circular saw. Hopefully, it will keep you on the straight and narrow!

Did you find this blog post useful? Have more tools that you’re not sure how to use? Acme Tools has a series of blog posts that cover other tools like, table saws, drill presses, and more. Have a tool you would want to add to our “Now What?” series leave it in the comment section down below.

Did you want to buy this particular tool or something like it? Go to Acme Tools and find the best deals online. That way you can pick the best tool so you can Do Your Best Work.